Key Takeaways

- Industrial supply chains are crucial for delivering efficient and cost-effective construction projects.

- Innovations like digital twins and blockchain technologies are transforming supply chain transparency and reliability.

- Sustainable supply chain practices are rapidly gaining ground, meeting both regulatory and environmental expectations.

Industrial supply chains are crucial to construction, affecting project speed and success. They do more than deliver materials; they optimize processes, reduce risks, and ensure resource availability. In a competitive market, understanding and improving supply chains is vital. For project managers, contractors, or suppliers, knowing best practices can prevent delays and overruns. For robust, solutions-driven partnerships and high-quality materials that keep supply lines moving, Cruco Mill & Industrial Supply is a trusted industry name among construction professionals nationwide.

The evolution of construction supply chains has focused on efficiency, transparency, and sustainability. Facing challenges like material shortages and the need for digital traceability, contractors adopt advanced technology and collaborative networks. This not only addresses market disruptions but also promotes smarter, resilient building practices.

The Role of Supply Chains in Construction

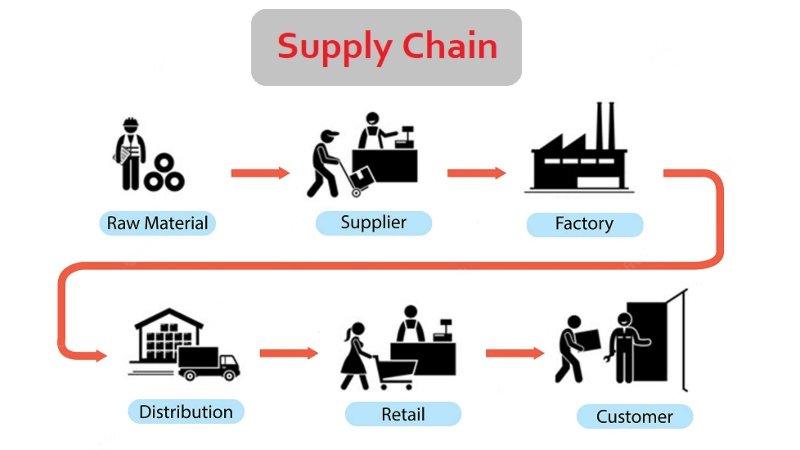

At its core, a construction supply chain manages the procurement, manufacturing, transportation, and timely delivery of building materials and equipment to project sites. Effective supply chain operations involve strategic supplier selection, robust logistics planning, and continuous risk management. When these systems fail, delays quickly accumulate, resulting in project bottlenecks and budget overruns.

As projects grow in both size and complexity, the orchestration of just-in-time deliveries, inventory management, and real-time data sharing becomes increasingly vital. Strategic improvement of supply chain processes can lower operational costs, reduce waste, and raise overall project quality.

Technological Innovations Transforming Supply Chains

Technological advancements, particularly digital twins and blockchain, are transforming supply chains in modern construction. Digital twins serve as virtual models that utilize sensor data and AI analytics to optimize scheduling and resource management, resulting in a 25% reduction in average delays. Blockchain enhances transparency by creating secure, auditable records for stakeholders, facilitating responsible procurement and effective compliance monitoring. Additionally, data analytics platforms improve forecasting and decision-making, enabling firms to maintain a competitive edge and mitigate disruptions.

Impact of Global Events on Supply Chains

Recent global shocks—from pandemic-related shutdowns to ongoing trade negotiations—have exposed weak points in construction supply chains. Fluctuations in tariffs, changing import/export policies, and a push toward onshore manufacturing are triggering widespread realignments. In the United States, such shifts are already impacting where and how materials are sourced, stored, and routed to worksites. These changes require a more agile and responsive approach to supply chain management.

Sustainability and Eco-Friendly Practices

Environmental considerations are taking center stage as supply chains evolve. Construction firms are progressively focused on integrating green procurement policies, such as sourcing recycled or locally produced materials and implementing closed-loop systems to minimize industrial waste. These steps not only reduce a company’s carbon footprint and align with new environmental regulations but also enhance its brand value and attractiveness to eco-conscious stakeholders.

Challenges in Supply Chain Management

While significant progress has been made, several persistent challenges continue to hinder further advancement. Material shortages due to global logistics complications and variable raw material demand often lead to supply gaps and production delays. Additionally, the complexities of logistics impact multi-site projects, making them vulnerable to disruptions in transportation and infrastructure limitations. Furthermore, the necessity to comply with evolving safety, quality, and sourcing regulations across different jurisdictions adds to project risk and complexity.

Strategies for Effective Supply Chain Management

To mitigate delivery risks, companies should employ integrated strategies, including supplier diversification to build relationships with multiple vendors, investments in technology such as cloud platforms and AI for better inventory management, and collaborative partnerships that foster transparency and shared goals among suppliers, shippers, and contractors.

Future Outlook

The path for construction supply chains is clear: embracing digital transformation, sustainability, and agile risk management positions companies to thrive. As expectations and regulations rise, innovation will accelerate. Proactively addressing vulnerabilities, forming strategic partnerships, and adopting new technologies will set industry standards for resilience and success. Industrial supply chains power modern construction. By innovating and integrating sustainability, the sector can deliver projects that are faster, efficient, responsible, and future-ready.