Many teams now look for practical ways to store goods with less effort. They want sturdy units that fit different site needs and support quick adjustments when demand shifts. They also want setups that keep goods safe without heavy construction. Modern inventory control relies on simple tools and flexible storage options that enable workers to track products in real time. These modern setups help teams shift from old routines to a more adaptive style that feels easier to handle each day.

Here are some clear methods that many teams use when they want better control of their stock:

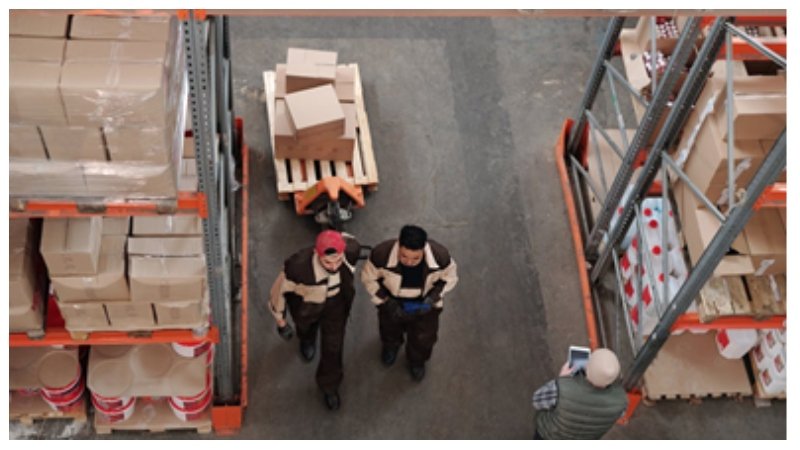

The Shift Toward Flexible Inventory Systems

Many teams use storage options that support quick changes during busy periods. These setups help workers sort items fast and keep goods in the right order. Workers also move goods with less effort because these options hold up well on different sites. Flexible storage gives teams room to adjust their stock plans across the year. This reduces confusion and helps each worker follow the same routine. Teams also shift goods between locations without delays. These simple setups help teams stay ready for changes in demand and help them avoid slowdowns that can disrupt daily work.

Using Portable Storage Solutions to Support Stock Movement

Many teams now use portable units to hold goods on job sites or move items to different areas. Some teams look for a shipping container for sale from reputable firms when they want a strong unit that handles frequent site changes. The units often come in a 20-foot size that offers thick steel walls, a weather-resistant design, and tamper-resistant locking. These units also give workers enough room to stack goods in a neat layout. The space supports quick loading routines and cuts down on clutter. These units help teams store goods in one place without extra setup work. This also helps workers keep track of items through simple daily checks.

Real-Time Tracking Tools for Clear Stock Visibility

Workers now use scanners and simple tracking tools to check stock from their devices. These tools help them log new items and spot low quantities without guesswork. Managers also use clear dashboards to see what moves fast and what needs attention. This gives them a steady flow of updates that helps them plan restocks. These tools help teams avoid errors that happen when workers track items by hand. The setup feels easy for teams because they check items as they go. This steady flow of updates helps everyone stay aligned during busy hours.

Cloud-Based Inventory Platforms for Multi-Site Control

Many teams use cloud systems to check stock numbers from different locations. Workers see updates right away and fix issues before they grow. These tools help workers stay on the same page even when they work in different areas. Managers also check movement trends and make quick adjustments when demand rises. Cloud systems help teams track items with ease and avoid confusion that comes from separate lists. This setup supports workers who move between sites because they always see the current numbers. The systems help teams keep their stock balanced simply and steadily.

Smart Sensors for Safer Stock Handling

Sensors help workers keep track of temperature, moisture, and movement inside storage units. These alerts help them protect items that need a controlled setting. Sensors also help teams catch issues before the goods face damage. Workers get alerts on their devices, which helps them act fast. These tools help workers avoid spoilage and keep fragile items in good condition. Sensors also make daily checks easier because workers rely on real-time readings. This setup helps teams stay confident that their stored goods hold up well during long shifts.

Inventory Forecasting with Simple Data Tools

Teams now use light data tools to plan stock needs without complex software. These tools use recent movement trends to show what items may move faster in the coming weeks. Workers adjust their stock plans based on these updates. This helps them avoid shortages while also avoiding piles of unused items. The short forecasts help managers place orders at a steady pace. The tools also help teams keep their shelves balanced across seasons. Workers feel more prepared because they use simple insights that support day-to-day decisions.

Mobile Apps for Quick On-the-Go Checks

Mobile apps help workers update stock from any area on site. They scan items, check quantities, and record movement in seconds. This helps teams skip long desk sessions and finish checks during their routine tasks. Apps help workers catch issues sooner because they update items right away. Managers also see these updates and make quick changes when needed. The apps help teams stay aligned during busy days because everyone sees the same numbers. This setup helps teams adjust to workload changes while keeping their stock in order.

Cross-Department Collaboration for Better Stock Control

Teams work better when groups share stock details with each other. Workers in receiving, storage, and supply roles stay aligned when they use shared tools. This helps them avoid mix-ups when items move between areas. Clear communication also helps workers refill items at the right time. Each group knows what the others need. This reduces slowdowns and gives teams a clear picture of their stock. A shared routine helps each group complete its part without confusion. Simple updates help teams keep their goods in order throughout the day.

Training Workers on Modern Inventory Tools

Training helps workers feel ready to use new tracking tools and storage setups. Short sessions help them learn scanning steps, dashboard features, and sensor alerts. Workers feel more confident when they learn these tools in small steps. They also ask questions and share feedback that helps the team improve daily routines. Good training reduces errors and helps new workers adapt faster. Teams also stay consistent because everyone follows the same process. This makes stock checks easier for the whole group.

Modern inventory control depends on simple tools, steady routines, and flexible storage options that help teams adjust to daily changes. Portable units, smart tools, mobile apps, and clear policies support workers who handle stock across different locations. These methods help teams keep items in good shape, track stock with ease, and stay aligned during busy cycles. When teams use tools that fit their daily needs, they keep their stock organized and ready for movement. This creates a clear and practical path for better control of goods in any work setting.

Please visit my site, Itbetterthisword, for more details.